Rapid Prototyping Services: Shaping Ideas into Reality

Introduction

Rapid prototyping services offer a cutting-edge solution for turning creative concepts into tangible models in a short time. Whether it’s for automotive components, medical devices, consumer products, or aerospace parts, these services have become the backbone of modern design and manufacturing.

This article explores how rapid prototyping works, its various methods, benefits, industrial uses, and why it is essential for businesses that aim to stay ahead in a fast-paced market.

What Is Rapid Prototyping?

Unlike traditional prototyping, which may take weeks or months, rapid prototyping significantly reduces development time by using computer-aided design (CAD) and additive or subtractive manufacturing methods.

Rapid prototyping services are offered by specialized firms or manufacturing partners who assist companies in developing and testing products faster, more affordably, and more accurately.

How the Process Works

Step 1: Concept and Design

This design forms the blueprint for the prototype and includes specific dimensions, tolerances, and details.

Step 2: Choosing the Method

Depending on the application, size, material, and purpose, manufacturers select a rapid prototyping technique. This can include 3D printing, CNC machining, vacuum casting, or injection molding.

Step 3: Production

Once the design and method are finalized, the prototype is produced using state-of-the-art machines. These services ensure fast turnaround, often delivering a working model within days.

Step 4: Evaluation and Iteration

Feedback from designers and engineers may lead to modifications and additional iterations before the final version is approved for mass production.

See also: How to Seamlessly Integrate Interactive Screens with Your Existing Tech Stack

Types of Rapid Prototyping Services

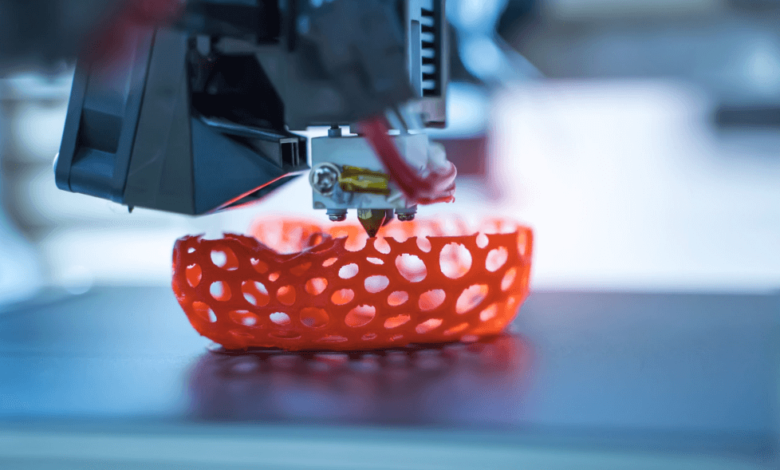

3D Printing (Additive Manufacturing)

This is the most common form of rapid prototyping. Layers of material—such as plastic, resin, or metal—are deposited one over the other to form the object. Techniques include:

- FDM (Fused Deposition Modeling)

- SLA (Stereolithography)

- SLS (Selective Laser Sintering)

- DMLS (Direct Metal Laser Sintering)

CNC Machining

CNC (Computer Numerical Control) machining uses subtractive manufacturing. This method is ideal for prototypes needing tight tolerances and high-quality finishes.

Vacuum Casting

This involves creating silicone molds from a master model. It’s a popular method for producing low-volume batches of plastic parts that resemble final production components.

Advantages of Rapid Prototyping Services

Speed to Market

The most obvious benefit is time. This speed accelerates innovation and gives companies a competitive edge

Cost Efficiency

Developing a prototype through traditional tooling is expensive. Rapid prototyping reduces tooling costs and allows for affordable low-volume testing before full-scale production.

Design Flexibility

Because iterations can be completed quickly, designers can explore various configurations, shapes, and styles without financial risk. This allows for creative freedom and better final outcomes.

Improved Product Testing

Functional prototypes allow for thorough testing of mechanical properties, ergonomics, and usability before committing to mass production.

Enhanced Collaboration

Having a physical model improves communication between engineers, designers, clients, and stakeholders. Feedback is more focused and productive when everyone can see and touch the design.

Applications Across Industries

Automotive

Automotive companies use rapid prototyping to develop parts like bumpers, dashboards, engine components, and even functional test rigs. It speeds up design cycles and allows performance testing before production.

Medical

In healthcare, prototypes help in the creation of surgical instruments, prosthetics, and diagnostic devices. Custom-fit models can be tailored to a patient’s anatomy for testing before actual use.

Aerospace

Rapid prototyping enables lightweight and complex part development.

Consumer Electronics

Gadget manufacturers rapidly prototype cases, buttons, internal frames, and connectors to validate the feel, function, and assembly of their products.

Industrial Equipment

Rapid prototyping supports engineers in developing housings, gears, and moving parts to test the mechanical function and durability of machinery components.

Choosing the Right Rapid Prototyping Partner

When selecting a provider for Rapid Prototyping Services the following:

- Technology Availability: Ensure the service offers a range of prototyping techniques like SLA, CNC, or casting.

- Material Options: Look for a provider that supports multiple materials, including thermoplastics, metals, resins, and composites.

- Lead Time: Choose a service that delivers within your required timeframe.

- Accuracy and Tolerance: Precision is critical for functional parts, so ensure they can meet the required tolerances.

- Experience and Support: An experienced team can guide you through the process and suggest design improvements.

Materials Commonly Used

Rapid prototyping offers an extensive selection of materials:

- Plastics: ABS, PLA, Nylon, PC, TPU, etc.

- Metals: Aluminium, stainless steel, titanium, etc.

- Resins: Standard, flexible, heat-resistant, or medical-grade

- Composites: Carbon fiber-filled or glass-filled materials for added strength

Rapid Prototyping and Sustainability

Modern prototyping services are becoming increasingly eco-conscious:

- Material Recycling: Leftover powder or unused filament is often recycled for future use.

The Future of Rapid Prototyping

The integration of AI-driven design, cloud-based collaboration tools, and machine learning in quality inspection will make rapid prototyping services even more efficient. 3D printing is evolving to handle more complex geometries, better materials, and higher precision—allowing prototyping to become indistinguishable from end-use part manufacturing in some applications.

Conclusion

Rapid prototyping services are transforming how ideas come to life. By reducing development time, lowering costs, and enhancing creativity, they empower businesses to innovate faster and smarter. Whether you’re launching a startup product or iterating on a high-performance engineering component, rapid prototyping stands as the foundation of agile and intelligent product development.

As industries evolve, so does the need for faster and more adaptive solutions. Rapid prototyping is not just a service—it’s a vital strategy for staying competitive in a world driven by speed, precision, and innovation.