self loading concrete mixer: The Evolution of Concrete Mixing Technology on Wheels

In the ever-evolving landscape of construction technology, efficiency, speed, and self-sufficiency have become the guiding principles for site operations. Among the machines redefining on-site construction practices, the Self Loading Concrete Mixer stands tall. With its ability to mix, load, transport, and discharge concrete—all through a single operator—it has revolutionized how builders think about concrete preparation and delivery.

This article delves into the journey, value, and functionality of the self loading concrete mixer, exploring how this machine is more than just construction equipment—it’s a modern-day construction enabler.

The Concrete Evolution: From Manual to Mobile

Traditionally, concrete mixing was a labor-intensive and time-bound activity. Workers had to manually measure materials, mix them in stationary drums, and transport the mix using wheelbarrows or transit trucks. Each step required manpower, coordination, and significant time investment.

As construction scales grew and projects became more complex, these traditional systems began to fail under pressure. Delays in concrete delivery meant work stoppages, structural inconsistencies, and rising costs.

The answer? Automation, mobility, and integration.

The self loading concrete mixer emerged to combine all essential concrete operations into a self-contained vehicle. It transformed a multi-step workflow into a streamlined process that one person can manage from the driver’s seat.

See also: The Future of Door Access: How Technology is Securing Modern Spaces

self loading concrete mixer: What Makes It Unique?

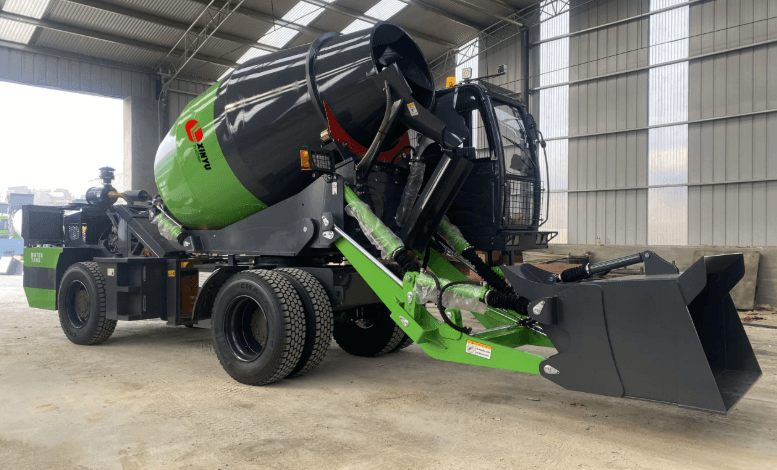

Unlike static mixers or transit trucks, the self loading concrete mixer performs the entire cycle of concrete preparation right on-site.

🔧 Key Functional Features:

- Hydraulic loading bucket to scoop and feed raw materials

- Rotating mixing drum with automated blade movement for consistent concrete

- Integrated water supply system with precise water measurement

- Operator cabin with panoramic visibility and joystick controls

- Drum tilting system for 270°–360° controlled discharge

- Heavy-duty wheels and 4×4 drive for rough terrain access

This integration allows builders to take concrete production wherever they go—even to isolated or unstructured job sites where traditional methods would fall short.

On-Site Convenience: The Modern Contractor’s Advantage

A major reason contractors and project managers prefer the self loading concrete mixer is its remarkable operational independence. Here’s how it simplifies the construction process:

✔️ Saves Time

The entire cycle of loading, mixing, and transporting takes just minutes. No more waiting for third-party deliveries or navigating supplier schedules.

✔️ Minimizes Human Error

Precise measuring and mixing systems help eliminate inconsistencies that often occur with manual labor.

✔️ Reduces Project Delays

By producing concrete on-demand, you reduce idle labor time and maintain construction momentum, even in adverse conditions.

✔️ Works in Any Location

Mountain roads, jungle paths, or city construction zones—the mixer’s all-terrain capabilities make it a mobile powerhouse.

Real-World Application: A Case-Based Overview

Let’s explore some typical scenarios where the self loading concrete mixer has proven invaluable.

🏗️ Rural Infrastructure Project

In regions where road access is limited, delivering ready-mix concrete becomes expensive and unreliable. A self-contained mixer eliminates this dependency by mixing concrete directly at the site, even with limited manpower.

🏘️ Urban Commercial Construction

In city projects where space is tight and logistics are challenging, this mixer allows production and pouring without occupying additional space for batching or storing materials.

Selection Tips: What to Look for

When choosing a self loading concrete mixer, tailor your choice to your project’s specific requirements. Here are the key specs to consider:

- Drum Volume: Choose between 1.2 m³ and 6.5 m³ based on daily concrete requirements.

- Engine Power: Diesel engines of 70–110 hp are ideal for rough terrain and full loads.

- Discharge Mechanism: Prefer 270° or full rotation models for flexible pouring.

- Weighing System: Ensure digital load cells are integrated for accurate batching.

- Water Tank Capacity: Larger tanks reduce the need for frequent refilling.

- After-Sales Support: Pick a model with easy parts availability and local service networks.

Trusted brands like Daswell, Ajax, Fiori, and Carmix have reliable reputations in both local and international markets.

Maintenance Guidelines for Long-Term Use

Taking care of your self loading concrete mixer ensures higher output and longer service life. Follow these simple rules:

- Clean the drum after every batch to prevent material hardening.

- Check hydraulic systems weekly for leaks and pressure consistency.

- Lubricate moving parts as per manufacturer guidelines.

- Monitor engine health, tire condition, and fuel levels regularly.

- Inspect safety systems like cameras, alarms, and emergency brakes.

Preventive care not only avoids downtime but also safeguards workers from unexpected breakdowns or operational errors.

Sustainability and Eco-Friendly Advantages

Modern construction is moving toward sustainability, and the self loading concrete mixer supports that shift:

- On-demand mixing reduces excess production and material wastage.

- Fewer trips to batching plants lower fuel consumption and emissions.

- Water-saving technology avoids over-dosing and runoff.

- Lower site disruption means minimal environmental impact.

With stricter green building codes emerging globally, this machine helps builders stay compliant and environmentally conscious.

Future-Proofing with Smart Tech

Next-generation self loading concrete mixers are embracing digital transformation. Expect to see:

- Telematics for tracking production, location, and fuel usage

- Remote diagnostics via mobile apps

- GPS-based route planning

- Electric and hybrid engine options

- AI-assisted batching systems

These features will help construction firms remain competitive in the age of digital construction.

Conclusion: Reinventing Concrete Productivity

The self loading concrete mixer is not just a piece of machinery—it’s a strategic tool for today’s construction demands. From reducing manpower and equipment clutter to increasing productivity and flexibility, this single machine is changing how contractors plan and execute their projects.

Whether you’re building housing blocks, roads, bridges, or emergency shelters, having a self loading concrete mixer on your job site means less waiting, fewer errors, and more control. It’s the logical choice for anyone looking to streamline concrete operations without compromising quality or reliability.